Smart mining offers technological solutions to the mining industry. It is meant to increase safety and production while lowering costs. It can also reduce the environmental footprint of a mine. In this article we discuss the ways that smart mining is implemented today – and how it is envisioned to be implemented in the future – to improve mining conditions and operations.

Smart Mining

The implementation of smart mining solutions has been growing for at least 20 years. The COVID pandemic has accelerated that growth. The need to manage operations remotely and reduce in-person interaction has driven the need for technology. As mining companies start using smart mining technology, they see its value firsthand and are increasing their investment in it.

Major Goals of Smart Mining

There are four key areas where smart solutions are used in the mining industry:

Safety

Keeping workers safe is not only the right thing to do but it saves money. We tend to focus on major mine disasters. But thousands of mine workers are injured on the job each year. According to the National Institute for Occupational Safety and Health (NIOSH), there were approximately 4,000 injuries annually across mines in all sectors from 2016 to 2019.

Increased Production

There are several ways in which smart mining solutions can increase production. One way is determining where to mine in the first place. Another is using real time data to identify weak areas in mining operations and improve them.

Lower cost

Automation is one aspect of increasing worker safety by preventing injuries. But it also lowers cost – in the long run. Autonomous mining equipment can work 24/7. Real time data collected from the equipment can identify areas to potentially lower costs and increase productivity. Artificial Intelligence (AI) and machine learning can improve operations.

Going Green

Mining companies are using technology to reduce their environmental footprint by reducing their use of energy and water. They are also finding ways to reduce emissions through the capture and disposition of the CO2 they generate.

How Smart Mining Meets Their Objectives

Here are a few specific smart mining solutions that are increasing safety and productivity, while reducing costs and environmental impact.

Smart Mining Safety Solutions

PPE

Northern Light Technologies (NLT) takes personal protective equipment (PPE) to the next level with their Eagle cap lamp. It has tracking and proximity tags that can warn miners when they are entering a dangerous area inside the mine. It can also start flashing a blue light to warn vehicle drivers that a worker is heading their way.

Prevention through Design (PtD)

The NIOSH has a Prevention through Design (PtD) initiative to encourage businesses to anticipate and design out hazards associated with the work environment. This includes tools, equipment, work processes – anything that creates a safer workplace.

Smart Mining Productivity Solutions

Two key technologies have increased productivity: autonomous vehicles and digital twins.

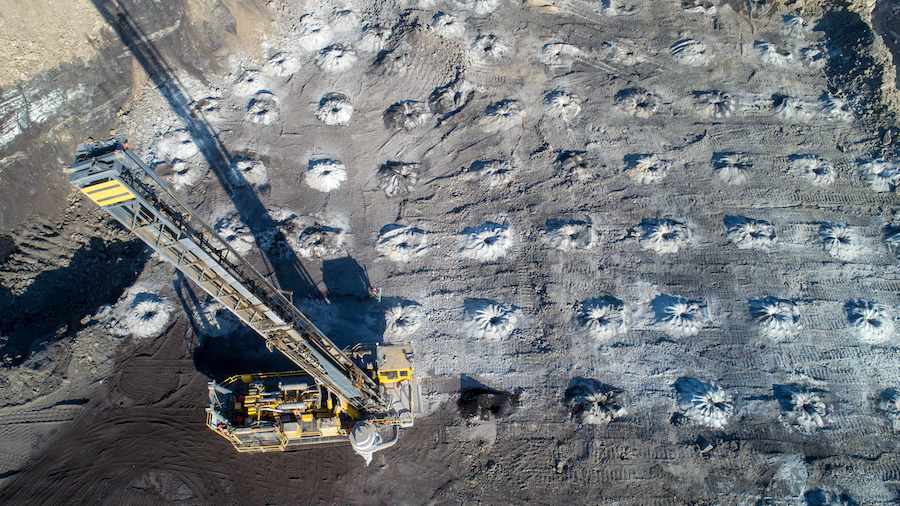

Autonomous Vehicles

Many types of autonomous vehicles (AVs) are now doing the dangerous work once performed by humans. These driverless vehicles are controlled remotely. For example, Volvo’s TA15 can haul up to 15-tons. Caterpillar claims that their suite of autonomous vehicles has safely hauled 2 billion tonnes. One challenge of AVs is teaching humans how to properly behave around them – so as not to cause accidents.

Digital Twins

A digital twin is a mine’s virtual copy of its operations. Real time data can be used to identify potential savings in the mine’s processes. Possible solutions can be virtually implemented to make better business and resource decisions. Several companies have digital twin offerings including GE Digital. The technology is prevalent enough that the Digital Twin Consortium announced in April of this year that it is collaborating with the Global Mining Guidelines Group.

Smart Mining Cost Reduction Solutions

Komatsu’s autonomous haulage system has saved from 50 cents to 62 cents per ton. ABB Ability™ MineOptimize solution claims an average overall savings of 25%.

Smart Mining Green Solutions

Reducing Emissions

Sempertrans and Dos Santos International (DSI) are using conveyer belt technology to replace trucks in the transport of materials. DSI’s sandwich belt high-angle conveyer can move material deep within a mine at a steep angle – or even completely vertically. It is two belts, face to face, that move material pressed between them. The Sempertrans TransEvo line of conveyor belts offers energy-saving belts that can reduce energy consumption by up to 25%. It achieves this through lower indentation rolling resistance.

Cleaner Coal

Clean coal sounds like an oxymoron to some. But it is achievable – to some measure. One key aspect of clean coal is carbon dioxide (CO2) capture and storage (CCS). This is a process where CO2 released from the coal burning process is captured, compressed, and dehydrated for transport and storage.

New Jobs in Mining

Let’s just be honest: Smart mining is displacing workers – underground. Above ground is where job opportunities are plentiful. According to the World Economic Forum (WEFORM) there are 10 positions that will be important to mining companies over the next four years. All are related to the implementation of smart mining technologies. They include big data specialists, AI and machine learning specialists, and process automation specialists. Mining Technology reports that software and web developers, programmers, and testers generated the highest share of mining hiring activity in April, 2021.

Future Smart Mining Technologies

The future of smart mining is in integration and continued digitization and remote operations. One major player in this space is ABB. The collection of data, along with the use of virtual technologies, is improving every aspect of mining. Rio Tinto has been on the leading edge of smart mining for years. One example is the Rio Tinto Visualization (RTVis™) 3D tool. It uses a gaming engine to “fly over a site and dive down to the detailed information we need.”

Conclusion

Mining companies that are embracing smart mining solutions are improving their operations for the better. The COVID pandemic showed that technology can help operations in sometimes unexpected ways. Remote operations, artificial intelligence, autonomous machines, and other components of smart mining are decreasing the need for physical human labor. But smart mining is creating many jobs above ground. The future of smart mining is moving the industry in ways it can only imagine. It has already improved operations in ways that were once the stuff of dreams just twenty years ago.

How does smart mining contribute to increased safety and reduced costs in the mining industry?

Smart mining utilizes technologies such as autonomous vehicles, digital twins, and safety solutions like Prevention through Design (PtD) and personal protective equipment (PPE) to enhance safety, increase productivity, and lower costs.

What job opportunities does the future of smart mining offer, and how is it impacting employment in the industry?

The future of smart mining introduces job opportunities in big data, AI, machine learning, and process automation, while displacing underground jobs with a shift towards roles like software developers and automation specialists.