A lot of construction, agriculture, and infrastructure jobs require heavy equipment, especially the kind that calls for an undercarriage mounted on a track system. Bulldozers, excavators, front loaders, and a number of other similar machines rely on tracks due to the need to work in a lot of different terrains, namely so that they can handle a variety of surfaces and conditions without worrying about shouldering the weight of the machine over wheels. But whether you own, lease, or rent your heavy equipment, you’ll have a decision to make about one of the most overlooked parts of the machine—the track.

What Does Your Track do for Your Equipment?

First, why even choose a tracked vehicle over a wheeled one? There are a lot of reasons. A track is going to last longer than most tires, which will reduce both your maintenance cost and your down time. With a larger surface area, tracked vehicles are also going to give you a lot more traction than wheeled equipment. Finally, by distributing their power equally, tracked vehicles simply have more power and stability than wheeled heavy equipment. But what should this track be made of?

When a runner breaks the world record, most people don’t immediately think, “I wonder what kind of sole he had on those sneakers,” even though they should. After all, the entire Nike company was started because University of Oregon running coach Bill Bowerman developed a specialized running sole by melting rubber on his wife’s waffle maker. She wasn’t thrilled, but it literally changed the world of athletic gear.

The track material is essentially the sole of the entire heavy equipment. First, depending on the material, it protects the road surface and prevents costly damage at the site. It also absorbs impact and helps distribute the weight of both the machine and any load it lifts, all while moving or stabilizing over terrain that is often uneven or organic. Depending on the material, the track will also reduce noise and vibration, which can extend the life of the entire piece of equipment.

Different Tracks for Different Jobs

If you’ve owned your equipment for any length of time, you might already be more familiar with steel tracks. It’s a time-honored system, whereas rubber tracks are still continuing to improve and change as the technology develops. On the other hand, you may have owned your equipment long enough to have also experienced a swap in your tracks, steel for some jobs and rubber for others.

Obviously, there are different tracks because they each have their own best-purpose. Some will be more suitable for asphalt road surfaces, while others will do better if you’re working in dirt and mud. If you’re looking for versatility due to the uncertain nature of your next contract, you can even go for bolt-on pads of different materials.

Rubber vs Steel Tracks

While some of the bolt-on track pads are made of polyurethane, two of the most common choices in tracks will be either rubber or steel. Both of them have their advantages, but they also both have their drawbacks depending on the nature of the job.

Deciding Between Rubber and Steel Tracks

So, with different options, how do you know what you need? Again, it’s going to come down to the terrain where you’ll be working, the kind of load you’re moving, and other factors.

Rubber Tracks:

- High level of traction on a variety of surfaces

- Best on grass or dirt, but better than steel for limiting damage to paved surfaces

- Lower noise due to less vibration

- Ideally suited for both construction and agriculture

- More cost effective to replace, but only last between 1200 and 1600 hours of standard use

Steel Tracks:

- Durable, able to withstand high heat and pressure

- Less susceptible to corrosion from chemicals commonly found on job sites

- More dependable on job sites that can have sharp debris

- Great on sites with a lot of inclines

- Usually last 2.5x longer than rubber tracks

Of course, what can seem like a disadvantage for one job can turn right around and be an advantage at another. For example, steel tracks are heavy. That means they run the risk of tearing up costly paving and using more fuel than equipment that’s outfitted with rubber tracks. At the same time, that added weight can make them more stable for lifting heavy loads, especially on uneven or unstable terrain. Again, it all comes down to what your job needs are.

Signs of Wear-and-Tear on Tracks

Regardless of the material and how long they’ll last, both rubber and steel tracks will start to show wear over time. Rubber tracks have some tell-tale signs that they’re about done, namely, visible cracking and damage in places, worn-out sprockets, problems with the track tension (either lack of tension or far too much tension), and an unsafe depth to the tread. If you can see exposed cords, missing lugs, visible and noticeable cracks, or have entire chunks of rubber coming off, it’s time for new rubber treads.

While steel tracks vastly outlast rubber tracks, nothing lasts forever. Maintaining your steel tracks with daily cleaning and inspecting, as well as ensuring the tension isn’t too tight, will go a long way towards extending the life of your heavy equipment and preventing undercarriage issues.

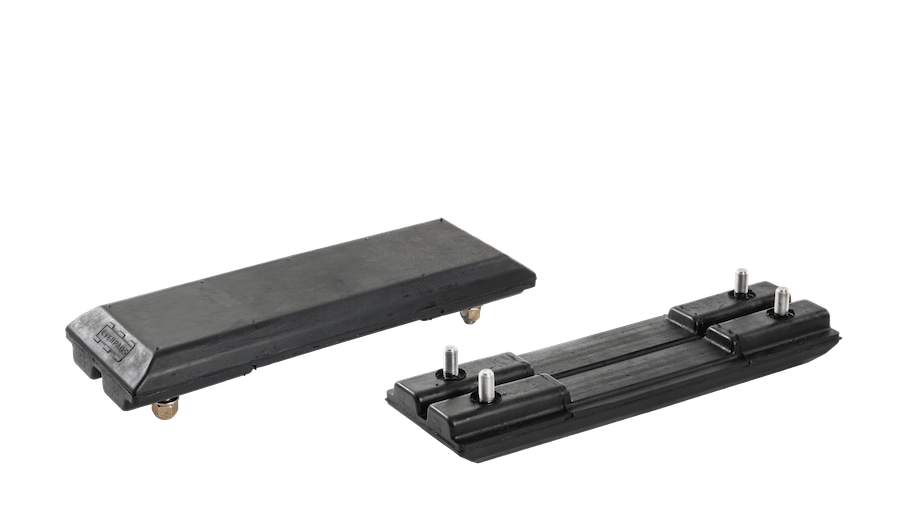

Versatility with Bolt-On Track Pads

While a lot of heavy equipment will take both steel or rubber tracks, there’s another really versatile option for most systems—bolt-on rubber track pads. This lets you enjoy the benefits of rubber tracks without having to swap out entirely. You’re also able to replace individual pads if corrosion or debris causes a sudden, serious problem. Companies like Everpads carry a full line of high-quality rubber pads for a variety of equipment and purposes, and they can advise operators of the best option for their needs; just be sure you’re not risking your equipment with pads made from subpar quality by companies that claim to offer a speedy, cheap fix.

Rubber track pads don’t just help you out, though. They’re a great solution if your next job involves terrain that could be damaged or destroyed by steel tracks. Thanks to rubber’s repulsion power and supporting force, their shock absorption capability means you can outfit your existing equipment for a job where less vibration and noise are important, too.

No Matter Which Option You Choose…

Regardless of whether rubber tracks or steel tracks are your best bet, proper maintenance and inspection will make a huge difference in keeping your equipment in working order. It goes without saying that checking the tracks, the sprockets, the treads, and the undercarriage after every shift will help you address any problems early on… before they become expensive or even dangerous.

What are the differences between steel and rubber excavator tracks?

Steel and rubber tracks differ in terms of durability, operating noise, and terrain adaptability. Steel tracks are known for their high durability and are ideal for tough terrains and heavy-duty tasks. They are more resistant to cuts and punctures but can be noisy and cause damage to paved surfaces. On the other hand, rubber tracks operate with less noise, cause minimal damage to surfaces, and provide a smoother ride. However, they might not be as durable as steel tracks and are more susceptible to wear and tear.

Which type of excavator track should I choose?

The choice between steel and rubber tracks depends on the work environment and the tasks at hand. Steel tracks are best for rough terrain and heavy-duty tasks, whereas rubber tracks are ideal for operations requiring less noise and minimal surface damage. It's important to assess the specific requirements of your project before choosing the appropriate track type.