- Low unfolding height as a major plus point

- LiDriveIn function for low entry into buildings

- Generous storage systems for hoses and pipelines

- Unique Liebherr Powerbloc drive unit

- Semi-closed oil circuit offers a multitude of benefits

The new 31 XXT truck mounted concrete pump from Liebherr offers particularly innovative technologies. This machine feels just as much at home on small to medium-sized construction sites as it does in buildings. The new LiDriveIn function and the low unfolding height make the pump a building professional.

Bad Schussenried (Germany) – After extensive testing, Liebherr now offers the smallest pump type from the 30-metre series. The 31 XXT with its particularly compact 5-part distribution boom scores with its low unfolding height of only 5.4 metres. This means maximum flexibility on smaller and cramped construction sites. The full strength of this concept is particularly noticeable when working indoors.

LiDriveIn

The new LiDriveIn function is a particular highlight when working in construction sites with low ceiling heights. Thanks to LiDriveIn, the 31 XXT can enter a building in standard operation with the arm package folded in front of the driver’s cab. To bring the arm package folded forward, it is not necessary to swing out the outrigger legs, it is only necessary to move the cylinders downwards. The machine operator lifts the cylinders again and can enter the hall together with the arm package in front of the driver’s cab. Now support can be provided as desired, for example full, partial or single-sided support. In the hall, the boom can be easily unfolded in front of the driver’s cab thanks to the short arm segments and the low unfolding height. This way, the last centimetres can be saved. For load reasons, the LiDriveIn function is only quoted in combination with a four-axle chassis.

Hose and pipe storage system: everything safely stowed away

Particularly ingenious storage systems for hoses and pipes allow around 90 metres of conveyor lines to be carried. After swinging out the outrigger legs, all bearing magazines are very well accessible. It is possible to store lines in diameters DN80/100/125. Due to the design of the magazine with individual pipes, each cable segment carried can be removed individually at will. According to the motto: Everything with you, everything individually removable, everything securely stowed away.

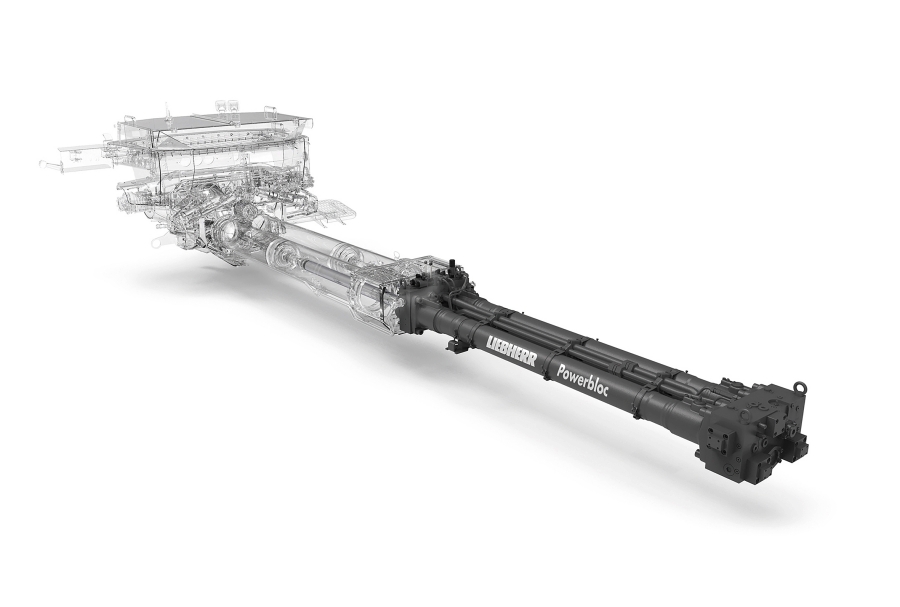

Unique Powerbloc drive unit

A major highlight of the new 31 XXT is Liebherr’s tried and tested “Powerbloc” pump drive unit. It is characterised by the fact that all hydraulic switching and measuring elements are fully integrated. This eliminates the need for numerous hydraulic hoses and other components previously required. The drive unit is therefore a special kind in the concrete pump world. Features of the new system are its robustness, high performance and quiet running.

Semi-closed oil circuit (HCC) reduces oil volume

The new drive unit is combined with the highly efficient semi-closed oil circuit, which supplies all drives powerfully and reliably with hydraulic energy. As a result, the oil volume could be significantly reduced. The new Liebherr system combines the advantages of the proven open and closed circuits currently on the market, without their respective disadvantages. Customers confirm the quiet and powerful operation of the pump unit.

Thanks to the extensive accessories catalogue, no wishes remain unfulfilled for the customer: For example, state-of-the-art LED lighting designs for optimal work in the dark, various storage boxes for materials and tools as well as shelves for hoses and pipelines are available.